Equipment Overview

The head stretching machine is one of the core equipment in the liquefied petroleum gas (LPG) cylinder production line. It is mainly used to form metal plates (usually high-quality carbon steel) into cylinder heads (hemispherical or ellipsoidal end caps) through cold stretching process. This equipment, in conjunction with a dedicated drawing die, ensures high dimensional accuracy and uniform wall thickness of the head, meeting the strict safety standards for pressure vessels.

Equipment composition and functions

1. Mainframe structure

It adopts a four-column or frame-type hydraulic press design, featuring high rigidity and strong resistance to eccentric loads.

The main oil cylinder drives the stretching slider to complete the bidirectional stretching action. The pressure is adjustable (usually 100-300 tons), suitable for the forming of heads of different specifications.

It is equipped with a hydraulic buffer system to prevent the sheet from cracking or wrinkling during the stretching process.

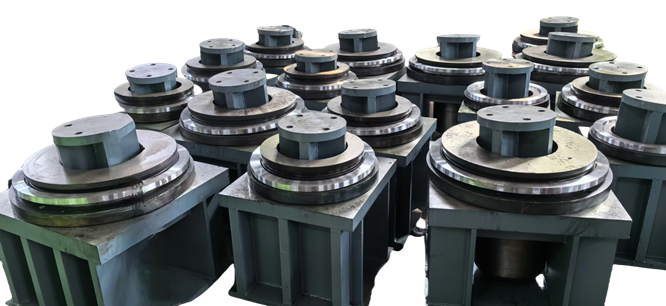

2. Stretching die

Material o: Die steel (such as H13) has undergone heat treatment and is hard chrome-plated on the surface, featuring excellent wear resistance.

o structure: It is divided into the convex die (upper die) and the concave die (lower die). The cavity is designed in accordance with GB/T 5842 or DOT standards to ensure that the curvature radius of the head and the edge transition meet the requirements.

Cooling system: The mold is equipped with built-in water channels, which control the forming temperature through the circulation of coolant and reduce material stress.

3. Automated auxiliary system

Automatic feeding device: Precisely position metal discs (billets).

Lubrication spray unit: Spray high-molecular lubricant on the blank before stretching to reduce the coefficient of friction.

o Waste stripping mechanism: Automatically separates the head from the scraps after molding.

Technical parameters

• Applicable materials: SPHC, Q345R and other steel plates with a thickness of 3 to 6mm.

• Forming accuracy: Diameter tolerance ±0.5mm, roundness ≤0.8mm.

• Production efficiency: Single cycle time ≤30 seconds (depending on specifications).

Safety and quality control

The equipment is equipped with photoelectric protection devices and emergency stop systems to prevent misoperation.

After stretching, the head needs to be inspected by an ultrasonic thickness gauge and appearance to ensure there are no cracks and the thinning rate meets the standards.

Application advantages

The one-piece forming process avoids welds and enhances the compressive strength of the gas cylinder.

The mold is modularly designed and can be quickly replaced to adapt to multi-specification production (such as 15kg and 50kg cylinders).