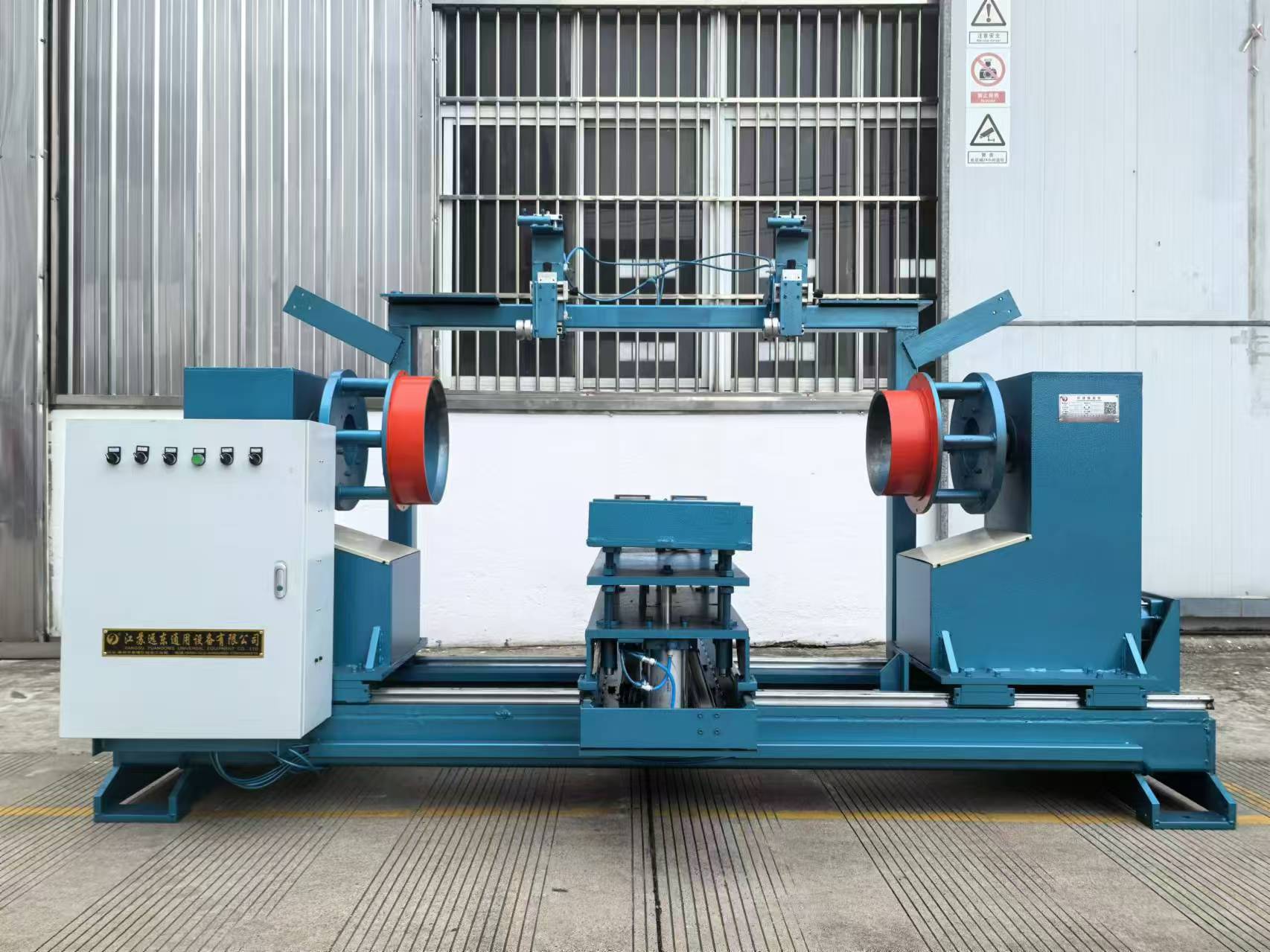

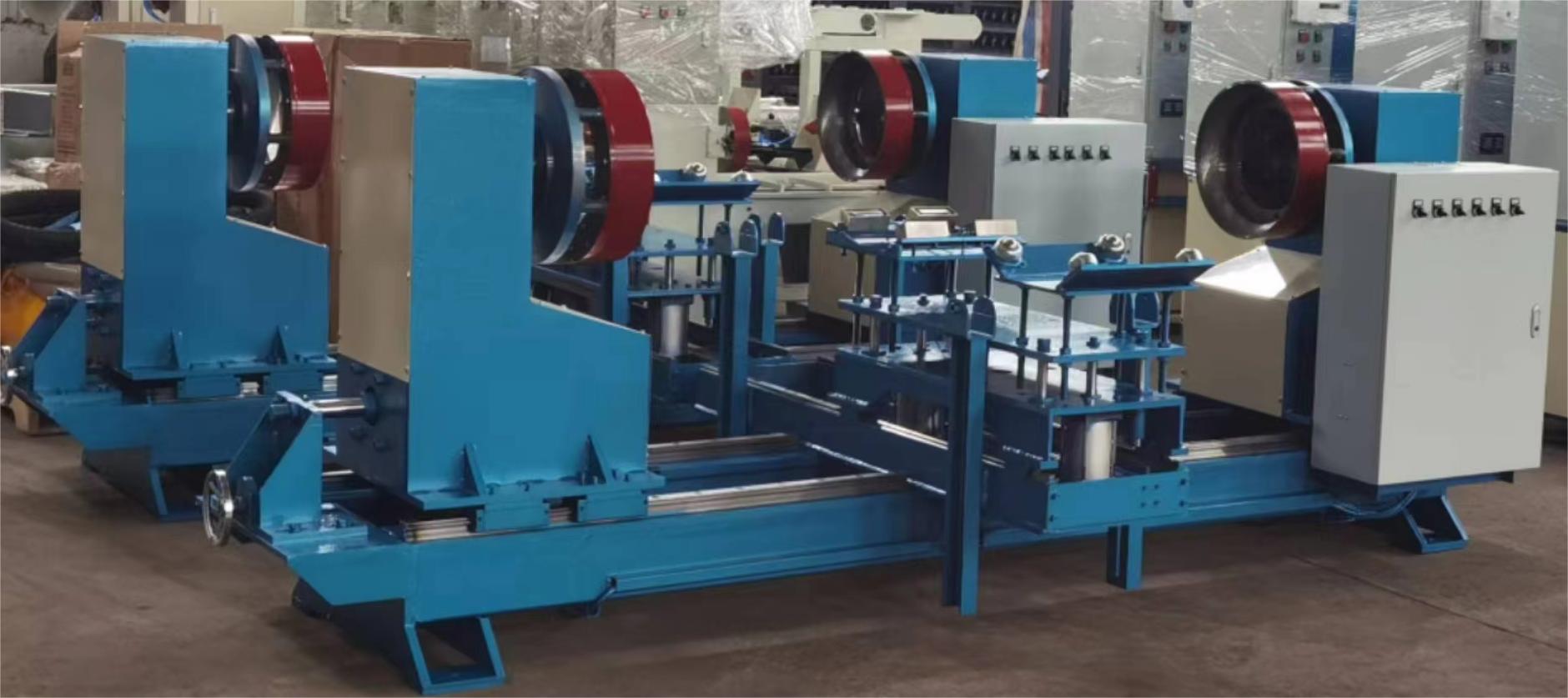

1. Equipment Overview

The automatic circumferential seam welding equipment for liquefied gas cylinders is a high-precision welding system specifically designed for the circumferential welds between the cylinder body and the head of the cylinder. It adopts automatic control technology to achieve continuous and stable welding operations. This equipment is applicable to the manufacturing of pressure vessels such as liquefied petroleum gas (LPG) cylinders and industrial gas cylinders, ensuring that the weld strength, sealing performance and pressure resistance comply with national standards (such as GB/T 5842, ISO 22991, etc.).

2. Core Components

• Welding mainframe: It adopts SAW (Submerged Arc Welding) or MAG (Active Gas Welding with a melting electrode) process, and is equipped with a highly stable welding torch and wire feeding mechanism.

• Positioner system: Dual-head synchronous drive of the positioner enables 360° uniform rotation of the gas cylinder, ensuring precise and controllable welding speed and Angle.

• Automated control system: PLC+ touch screen integrated control, with preset welding parameters (current, voltage, rotational speed, swing amplitude, etc.), and supports multi-group program storage.

• Weld seam tracking device: Laser or visual sensors monitor the weld seam position in real time, automatically correct deviation, and ensure the consistency of the welding trajectory.

• Safety protection: Equipped with gas leakage detection, emergency stop button and protective cover, it complies with CE or OSHA safety standards.

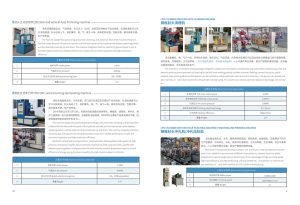

3. Technical Features

• High-precision welding: The welding speed range is 0.5-1.5m/min, the repeat positioning accuracy is ≤±0.1mm, and the weld formation is uniform without pores.

• Adaptive process: It can automatically adjust the heat input according to the material of the cylinder (such as HP295, HP345 steel plates) and thickness (2.5-6mm), avoiding burn-through or incomplete fusion.

• Dual-station design: Supports simultaneous loading and unloading as well as welding, increasing production efficiency by over 30%.

4. Application advantages

• Quality improvement: Automated welding reduces human errors, and the pass rate of X-ray inspection of weld seams is ≥99.5%.

• Cost savings: Compared with manual welding, the utilization rate of consumables is increased by 20% and energy consumption is reduced by 15%.

• Strong compatibility: It can be adapted to various cylinder specifications with diameters ranging from Φ200 to Φ600mm and lengths from 300 to 1200mm.

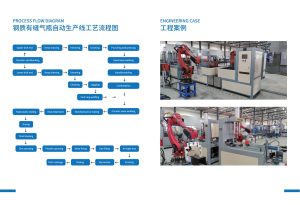

5. Typical workflow

1. Feeding and positioning: The cylinder body and the head are assembled into the positioner fixture by manual or mechanical hand.

2. Parameter Settings: Select the preset program or input parameters such as welding current (80-200A) and shielding gas flow rate (10-15L/min).

3. Automatic welding: After startup, the equipment completes the circumferential seam welding, and the welding torch automatically lifts to reset.

4. Blanching inspection: After welding is completed, manual inspection or linkage with automated flaw detection equipment.

6. Customized Services:

Personalized solutions can be provided based on customer demands. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process requirements of different customers.

.jpg)