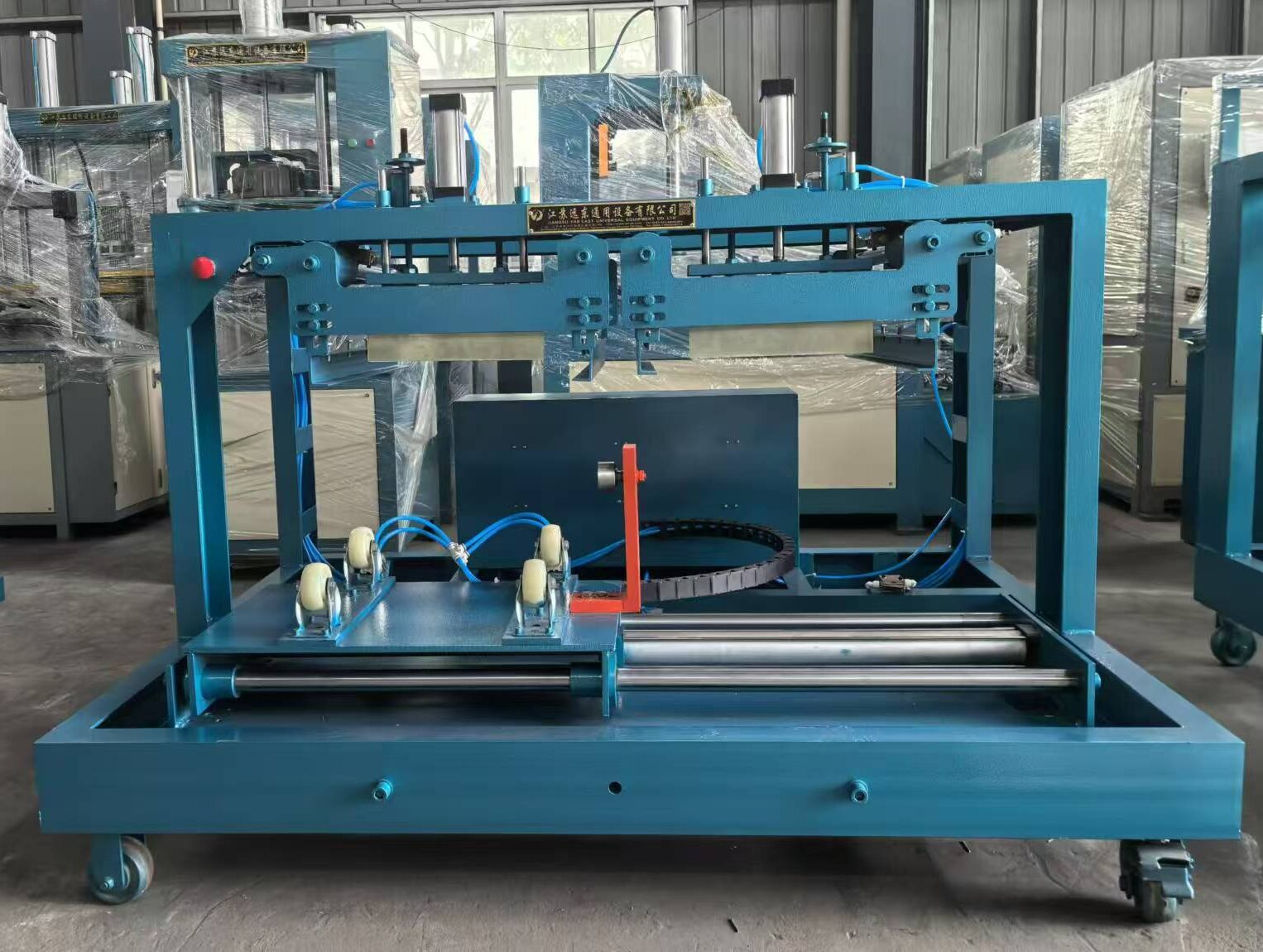

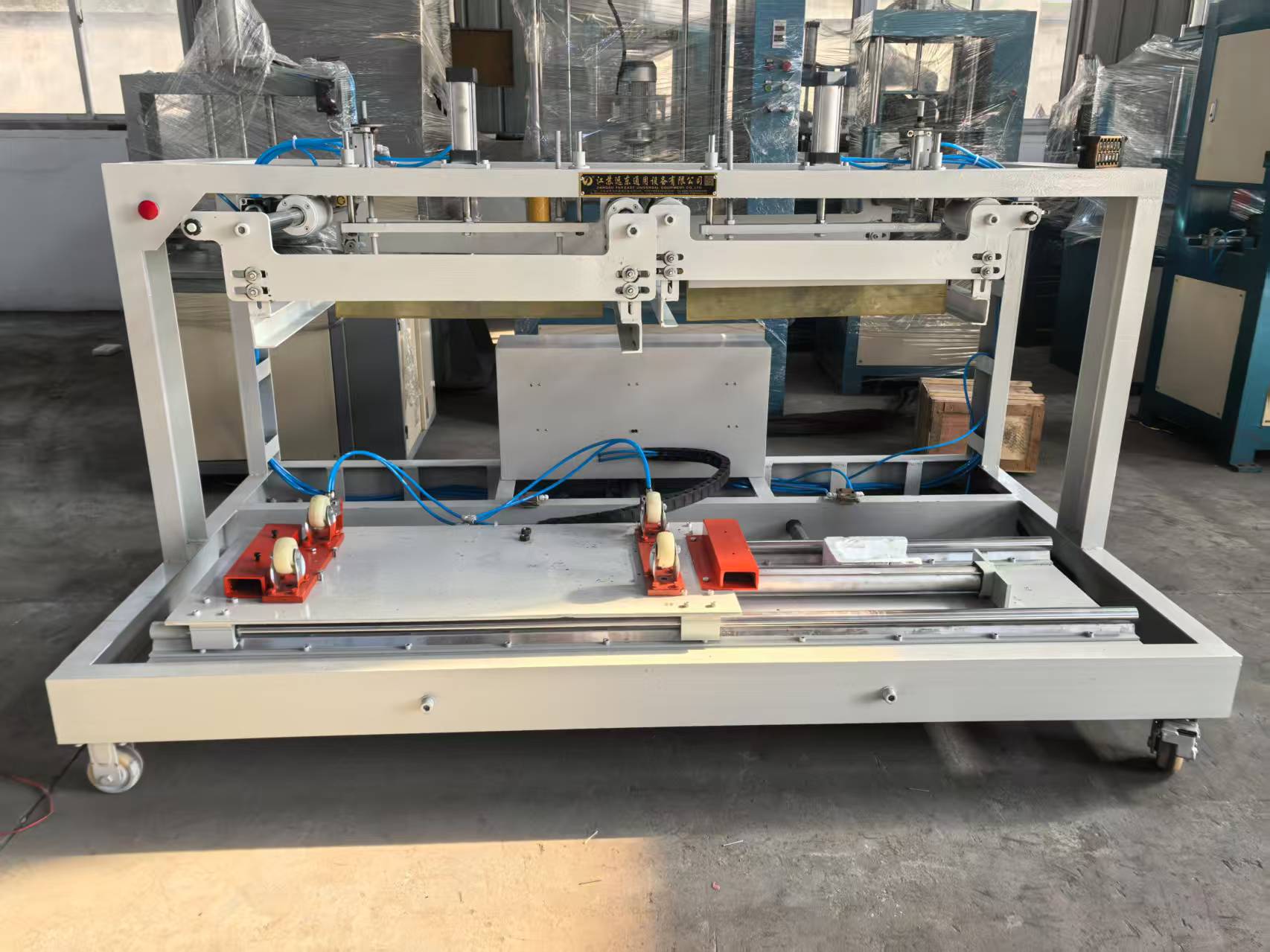

Product Overview

This equipment is a semi-automatic double-sided printing machine specially designed for liquefied petroleum gas (LPG) cylinders. It can efficiently and accurately print text, numbers, barcodes, logos and other contents on both the front and back of the cylinders. Adopting a human-machine collaboration mode, it is easy to operate and suitable for medium and small batch production or the inspection and refurbishment of gas cylinders, ensuring clear and durable markings and meeting industry safety standards.

________________________________________

Main functions and features

1.Double-sided synchronous/alternating printing

It can complete the printing of characters on both the front and back sides of the gas cylinder at one time, reducing manual flipping operations and improving production efficiency.

It supports manual feeding and automatic positioning printing, suitable for different production rhythm requirements.

- High-precision inkjet/pneumatic marking (optional)

Inkjet printing: Utilizing high-adhesion environmentally friendly ink, it is corrosion-resistant and wear-resistant, ensuring long-term clarity without fading.

Pneumatic marking (optional) : Suitable for occasions where permanent marking is required, such as steel stamp serial numbers, production batch numbers, etc.

- Flexible and adjustable, with strong adaptability

It can be adapted to LPG cylinders of different specifications such as 15kg and 50kg, and the adjustment mechanism is simple and fast.

It supports the printing of Chinese and English, numbers, barcodes, QR codes and enterprise logos, and the content can be customized.

- Semi-automatic human-machine collaboration

After the gas cylinders are placed manually, the equipment automatically completes the positioning and printing, reducing the operational difficulty.

It is controlled by a touch screen and can store multiple sets of printing templates, with convenient switching.

- Stable and durable, with easy maintenance

It adopts industrial-grade core components, has a low failure rate and is suitable for long-term use.

The open structure design makes it easy to clean and replace consumables.

________________________________________

Technical parameters

- Applicable objects: LPG cylinders, industrial gas cylinders and other cylindrical containers

- Printing method: Inkjet printing (standard)/Pneumatic marking (optional)

- Printed content: text, numbers, barcodes, QR codes, logos, etc

- Printing speed: 3-5 per minute (depending on the manual feeding speed)

- Positioning accuracy: ±1mm

________________________________________

Core advantage

- High cost performance: The semi-automatic design reduces equipment costs and is suitable for medium and small-scale production.

- Simple operation: Manual feeding + automatic printing, no complex training is required to get started.

- Durable marking: Both the ink and the steel seal comply with the GB/T 5842 standard, and are resistant to high temperatures and corrosion.

- Flexible adaptation: The printed content and position can be quickly adjusted to meet diverse needs.

________________________________________

Typical application scenarios

The end marking station of the LPG cylinder production line

Re-coding of gas cylinders after regular inspection

Double-sided printing on metal containers such as industrial gas cylinders and fire cylinders

Customized Services:

Personalized solutions can be provided based on customer demands. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process requirements of different customers.