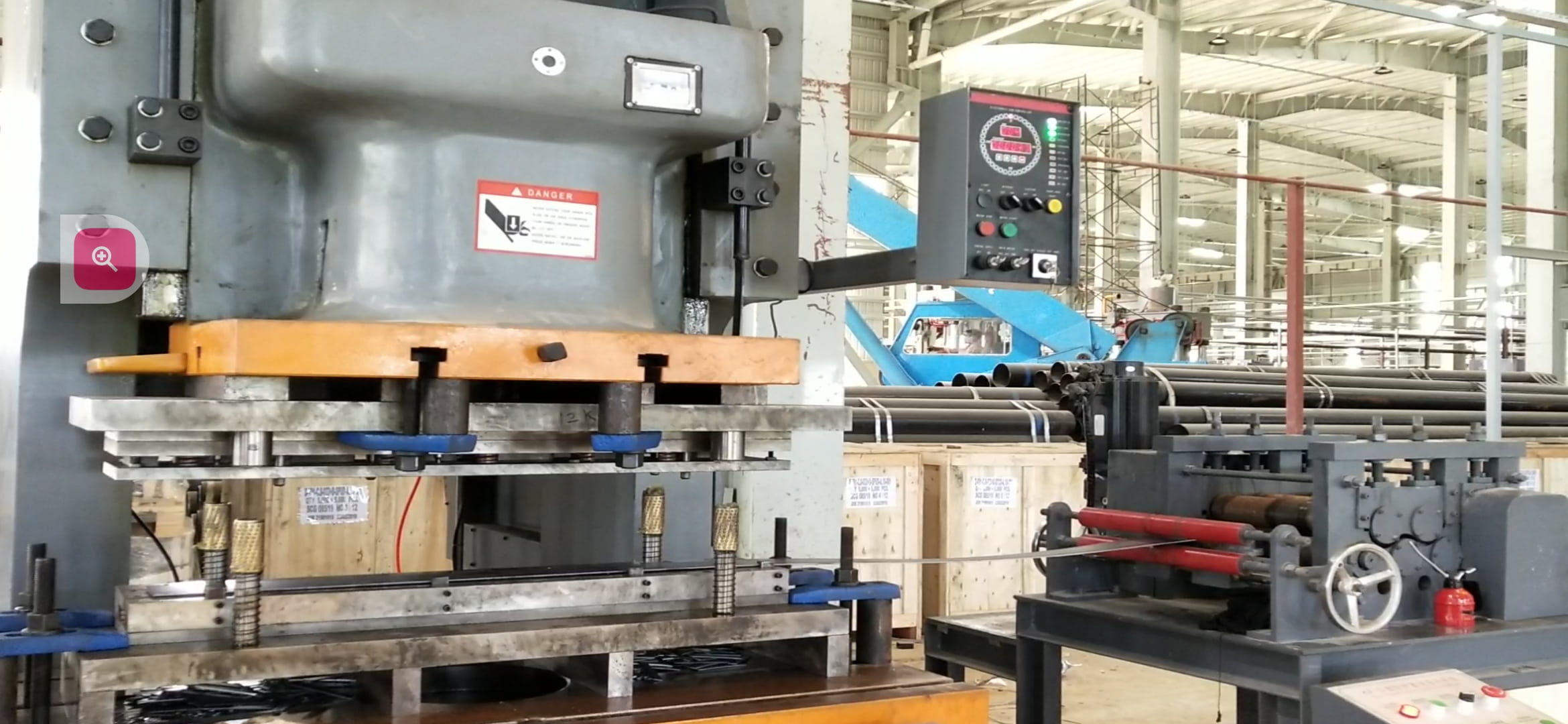

This production line is suitable for the coil material uncoiling first, then fed to the straightener-feeder, cutting the steel into the required size. It adopts computer optimization design, with high mechanical strength, operating smoothly. Control parts use digital circuits, servo drive, touch screen setup parameter, feeding length can be Flexible and adjustable, accurate and reliable. The whole production line is with high automation, stable operation, low failure rate, convenient maintenance. It is the first choice of LPG cylinder manufacturing machines.

Personalized solutions can be provided based on customer demands. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process requirements of different customers.

卷板开平落料线Handle-Footringblanking-production-line-Decoiler-straightener-feeder.jpg)

卷板开平落料线Handle-Footringblanking-production-line-Decoiler-straightener-feeder.jpg)