- Equipment Overview

The longitudinal seam welding machine for liquefied petroleum gas cylinders is a specialized equipment specifically designed for the automatic welding of longitudinal welds in cylinder bodies. It typically employs submerged arc welding (SAW) or gas shielded welding (MIG/MAG) processes to ensure high strength and high sealing performance of the welds, meeting national standards such as GB/T 5842 and ISO 22991.

________________________________________

Ii. Main Component Structure

- Host framework

The rigid welded bed is equipped with high-precision guide rails to ensure the stability of the welding process.

The adjustable fixture system is suitable for cylinder bodies of different diameters (commonly Φ300mm to Φ600mm) and lengths (1m to 2m).

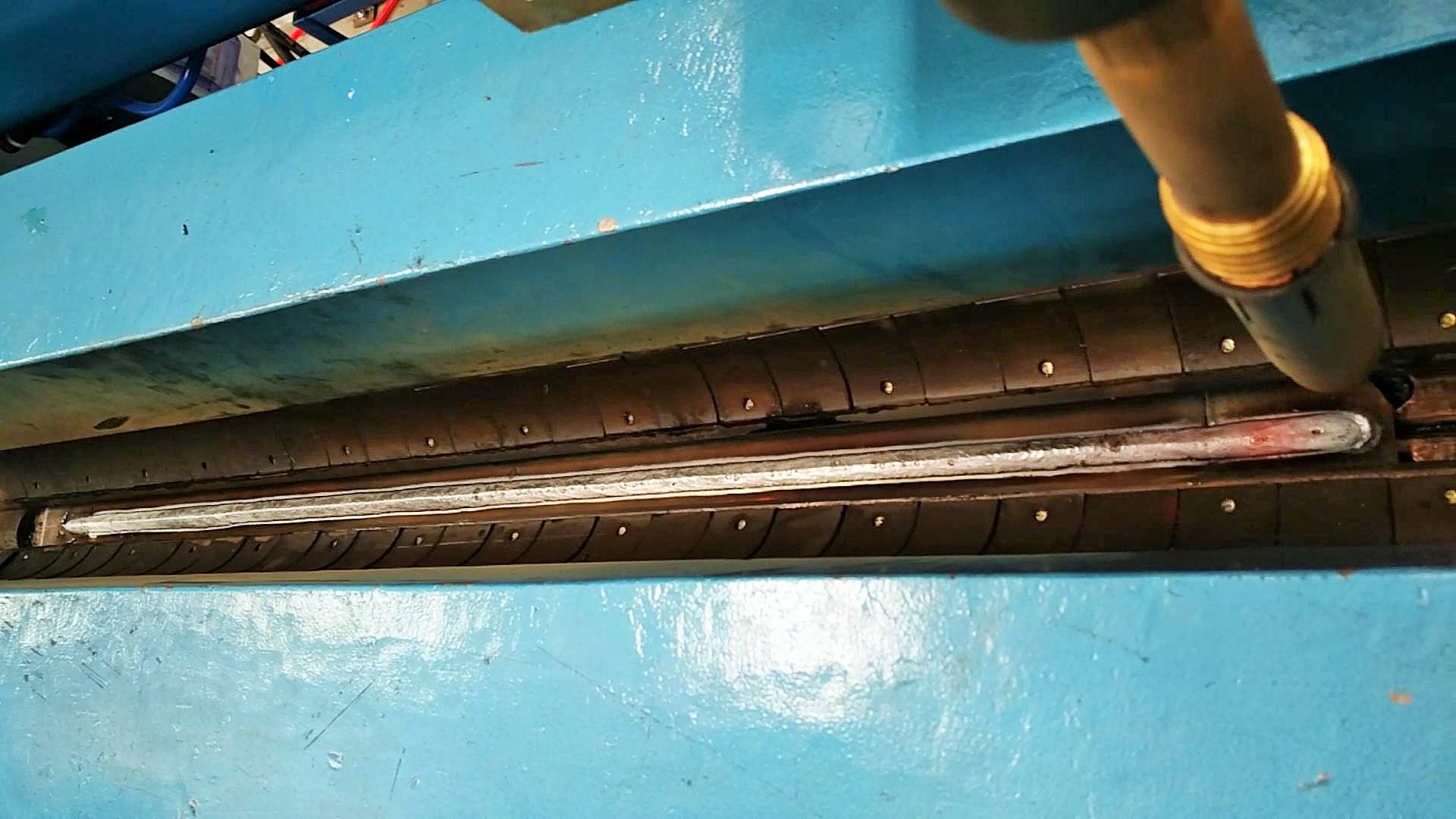

- Welding system

o welding torch mechanism: Driven by servo motors, it achieves multi-axis linkage (X/Y/Z axes), precisely controlling the position of the welding torch.

Flux conveying and recovery device (applicable to submerged arc welding) : Automatically conveys and recovers flux to reduce waste.

o shielding gas system (applicable to gas shielded welding) : Equipped with flowmeters and solenoid valves to ensure that inert gases (such as CO₂/Ar) cover the welding area.

- Transmission system

The roller frame is driven by variable frequency speed regulation or servo motor to achieve uniform rotation of the cylinder (speed range 0.1 to 1.5m/min).

The o centering device ensures that the longitudinal seam of the cylinder is always in the optimal welding position.

- Control system

o PLC+ touch screen human-machine interface, preset welding parameters (current, voltage, speed).

It can monitor the welding status in real time and has a fault alarm function (such as arc breakage and insufficient gas).

________________________________________

Iii. Key Technical Parameters

Project parameter range

Applicable cylinder thickness: 2.5 to 6mm (low-carbon steel or high-strength steel)

Welding speed: 0.2-1.2m/min (adjustable)

Welding current: 150-400A (selected according to the process)

Power supply voltage: 380V/50Hz (three-phase)

The positioning accuracy is ≤±0.1mm

Protective gas flow rate: 15-25L/min (for MAG welding)

________________________________________

Iv. Work Process

- Loading and positioning: Hoist the cylinder formed by the rolled plate onto the roller frame, clamp it with the fixture and align it with the longitudinal seam.

- Parameter Settings: Input parameters such as welding current, voltage, and speed (preset programs can be called).

- Welding startup: The welding torch automatically descends to the arc starting point, the cylinder rotates and completes single or multiple welding passes.

- Quality Inspection: Automatically inspect the appearance of the weld seam after welding (manual or visual system assistance for flaw detection is required).

________________________________________

- Safety and Maintenance

- Safety measures

Equipment grounding, arc radiation protection cover.

Emergency stop button and gas leakage sensor.

- Daily maintenance

Regularly clean the welding slag and check the wear of the conductive nozzle.

Calibrate the alignment of the welding torch and the accuracy of the transmission system.

________________________________________

Vi. Application Advantages

- High efficiency: Compared with manual welding, the speed is increased by 3 to 5 times.

- High consistency: Automation avoids fluctuations in human operation.

- Compliance: The weld seams are inspected by X-ray or ultrasonic waves and meet the standards for pressure vessels.

Vii. Customized Services

We can provide personalized solutions based on customer needs. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process requirements of different customers.