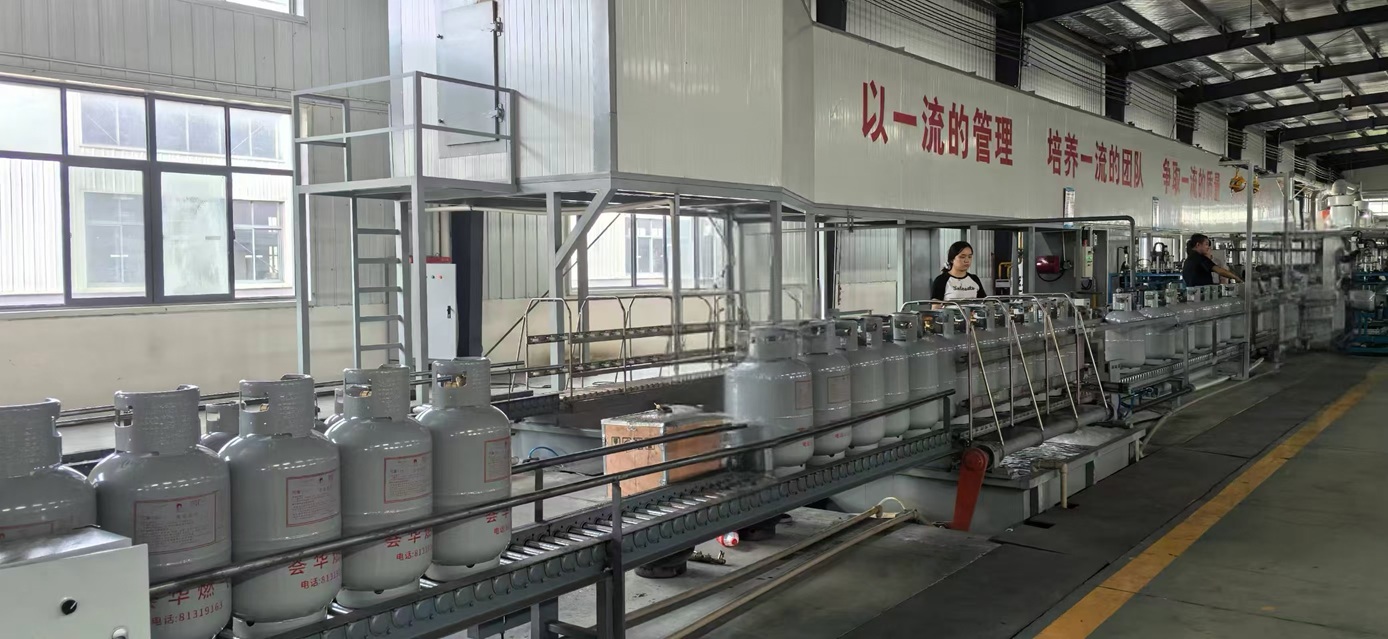

- Equipment Overview

- Function: It conducts automated airtightness testing on liquefied petroleum gas cylinders (LPG cylinders), determining whether there is any leakage by going through steps such as inflation, pressure holding, and detection.

- Flip design: During the testing process, the cylinder is held by mechanical fixtures and flipped 180° to ensure that the testing liquid (such as water or soapy water) covers all welds and interfaces of the cylinder body, enhancing the accuracy of leakage point identification.

- Through-type structure: The cylinders are automatically fed in, tested, and discharged, seamlessly integrating with the conveyor line, making it suitable for assembly line operations.

- Core Components

- Conveying System: Connects with the production line conveyor (such as roller conveyor or chain plate conveyor) to automatically transport the gas cylinders to the workstations.

- Inversion Mechanism: A fixture driven by a servo motor or cylinder that clamps the gas cylinder and then flips it to immerse it in the testing liquid.

- Airtightness Testing System:

o Inflation Unit: Fills the gas cylinder with compressed air or nitrogen (typically pressurized to the design pressure, such as 1.5 times the working pressure).

o Pressure Holding Module: After stabilizing the pressure, it determines leakage through a pressure sensor or bubble observation.

o Leakage Judgment: Pressure decay method or visual inspection (bubble method).

- PLC Control: Fully automated process, allowing the setting of parameters such as pressure and time, and recording of testing data.

- Connection Method with the Conveyor Line

- Butt Joint Design:

o Inlet/Outlet Roller Conveyor: At the same height and pitch as the workshop conveying line.

o Stopping Mechanism: Cylinder-driven stop bar or lifting platform to ensure the cylinders are precisely positioned at the inspection station.

o Transition Guide Rails: To prevent the cylinders from shifting during rotation.

- Synchronous Control: Through PLC signal interaction with the conveying line (such as start/stop, fault feedback) to achieve rhythm matching.

- Work Process

- Loading: The conveyor line feeds the gas cylinders into the testing machine, and the positioning fixture clamps them tightly.

- Pressurization: The gas valve is automatically connected for pressurization, and the pressure is maintained for a certain period of time.

- Inversion Inspection: The gas cylinders are inverted and immersed in a water tank or sprayed with detection liquid to observe bubbles (or analyzed through a pressure sensor).

- Drainage and Reset: The internal gas/liquid is drained, and the cylinders are inverted back to their original position.

- Unloading: Qualified products are conveyed to the next process, while unqualified ones are sorted and removed.

- Technical Advantages

- High Efficiency: The through-type design has a fast cycle time, making it suitable for large-scale production.

- High Precision: The flipping mechanism ensures no blind spots for inspection, and the pressure sensor accuracy can reach ±0.1% FS.

- Compatibility: It can be adapted to different specifications of gas cylinders (by changing the fixture or adjusting parameters).

- Application Scenarios

- Liquefied petroleum gas cylinder manufacturing plants

- Regular inspection stations for cylinders

- Industrial gas container production lines

- Customized Services:

- We can provide personalized solutions based on customer requirements. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process needs of different customers.