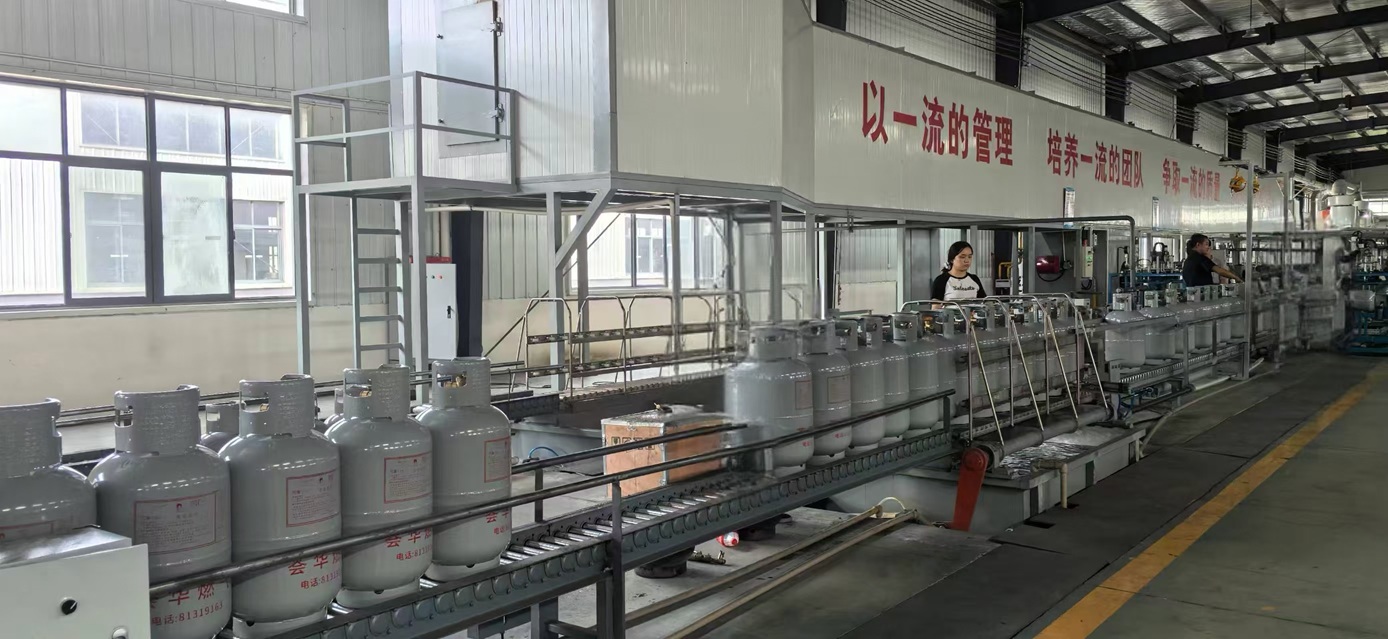

Equipment Overview

Function: It conducts automated airtightness testing on liquefied petroleum gas cylinders (LPG cylinders), determining whether there is any leakage by going through steps such as inflation, pressure holding, and detection.

Flip design: During the testing process, the cylinder is held by mechanical fixtures and flipped 180° to ensure that the testing liquid (such as water or soapy water) covers all welds and interfaces of the cylinder body, enhancing the accuracy of leakage point identification.

Through-type structure: The cylinders are automatically fed in, tested, and discharged, seamlessly integrating with the conveyor line, making it suitable for assembly line operations.

Core Components

Conveying System: Connects with the production line conveyor (such as roller conveyor or chain plate conveyor) to automatically transport the gas cylinders to the workstations.

Inversion Mechanism: A fixture driven by a servo motor or cylinder that clamps the gas cylinder and then flips it to immerse it in the testing liquid.

Airtightness Testing System:

o Inflation Unit: Fills the gas cylinder with compressed air or nitrogen (typically pressurized to the design pressure, such as 1.5 times the working pressure).

o Pressure Holding Module: After stabilizing the pressure, it determines leakage through a pressure sensor or bubble observation.

o Leakage Judgment: Pressure decay method or visual inspection (bubble method).

PLC Control: Fully automated process, allowing the setting of parameters such as pressure and time, and recording of testing data.

Connection Method with the Conveyor Line

Butt Joint Design:

o Inlet/Outlet Roller Conveyor: At the same height and pitch as the workshop conveying line.

o Stopping Mechanism: Cylinder-driven stop bar or lifting platform to ensure the cylinders are precisely positioned at the inspection station.

o Transition Guide Rails: To prevent the cylinders from shifting during rotation.

Synchronous Control: Through PLC signal interaction with the conveying line (such as start/stop, fault feedback) to achieve rhythm matching.

Work Process

Loading: The conveyor line feeds the gas cylinders into the testing machine, and the positioning fixture clamps them tightly.

Pressurization: The gas valve is automatically connected for pressurization, and the pressure is maintained for a certain period of time.

Inversion Inspection: The gas cylinders are inverted and immersed in a water tank or sprayed with detection liquid to observe bubbles (or analyzed through a pressure sensor).

Drainage and Reset: The internal gas/liquid is drained, and the cylinders are inverted back to their original position.

Unloading: Qualified products are conveyed to the next process, while unqualified ones are sorted and removed.

Technical Advantages

High Efficiency: The through-type design has a fast cycle time, making it suitable for large-scale production.

High Precision: The flipping mechanism ensures no blind spots for inspection, and the pressure sensor accuracy can reach ±0.1% FS.

Compatibility: It can be adapted to different specifications of gas cylinders (by changing the fixture or adjusting parameters).

Application Scenarios

Liquefied petroleum gas cylinder manufacturing plants

Regular inspection stations for cylinders

Industrial gas container production lines

Customized Services:

We can provide personalized solutions based on customer requirements. Specific parameters and functions can be adjusted according to the actual equipment configuration to meet the process needs of different customers.