Gas bottle testing equipment in the inspection, the main will be divided into two parts, in the first place, it is to pay attention to the regular inspection of a purpose; In the following words, we actually need to pay attention to their periodic inspection of a cycle, Gas Cylinder Testing Equipments for such a distinction, In fact, it is convenient for us to learn about this knowledge, but also to more in-depth understanding of the gas bottle test equipment.

Next, we actually should pay attention to look at the gas bottle test equipment itself has the main function; the 1th point, in fact, is that it has two different control methods, in which the main will include manual control and its automatic control, in between, in fact, is independent of each other, In this way, Gas Cylinder Testing Equipments we can actually use it separately.

Cylinder test equipment in the speed of the step-up in fact, can be adjusted by itself; the next words, for its entire test time speaking, in terms of its unit can be: seconds, minutes, Gas Cylinder Testing Equipments hours and days to be expressed; for the unit of its pressure, we can actually change the time.

Finally, on the gas bottle test equipment in the work, we are actually to pay attention to, about gas cylinders, it is actually able to adjust the output liquid in the pressure is very low, then, in fact, Gas Cylinder Testing Equipments can be directly on the different multi-level pressure treatment, more important point, The cylinder test equipment can automatically calculate the deformation rate of the volume.

When it comes to gas bottle testing equipment, in terms of its detection scope, for its gas bottle detection line is actually directly applicable in the design and its manufacturing nominal work pressure is actually the 16-25mpa, in terms of its nominal volume, in fact, it will be 30-200l, immediately thereafter, In the gas cylinder test equipment to meet the compressed natural gas with the same type or the specification of the steel inner liner ring to the winding cylinder periodic inspection and evaluation.

Next, when it comes to gas bottle test equipment on the technical parameters of gas cylinders, in fact, it is in the outer diameter of the cylinder in terms of φ219-φ426mm, then, for its gas bottle length is actually the words will be in 600-2000mm, finally, for its cylinder weight: ≤160kg, Gas Cylinder Testing Equipments In the form of its cylinders a (bottom), form B (concave bottom), in its form C (two bottles).

For the overall performance of the cylinder test equipment, in fact, in a large extent, it will be directly satisfied with the annual inspection of natural gas bottles 5000-15000. Then, Gas Cylinder Testing Equipments for its own equipment to say, that is, will be suitable for different specifications of the gas cylinders on the comprehensive on-line inspection, to meet the relevant national regulations and its standards for natural gas cylinders inspection requirements.

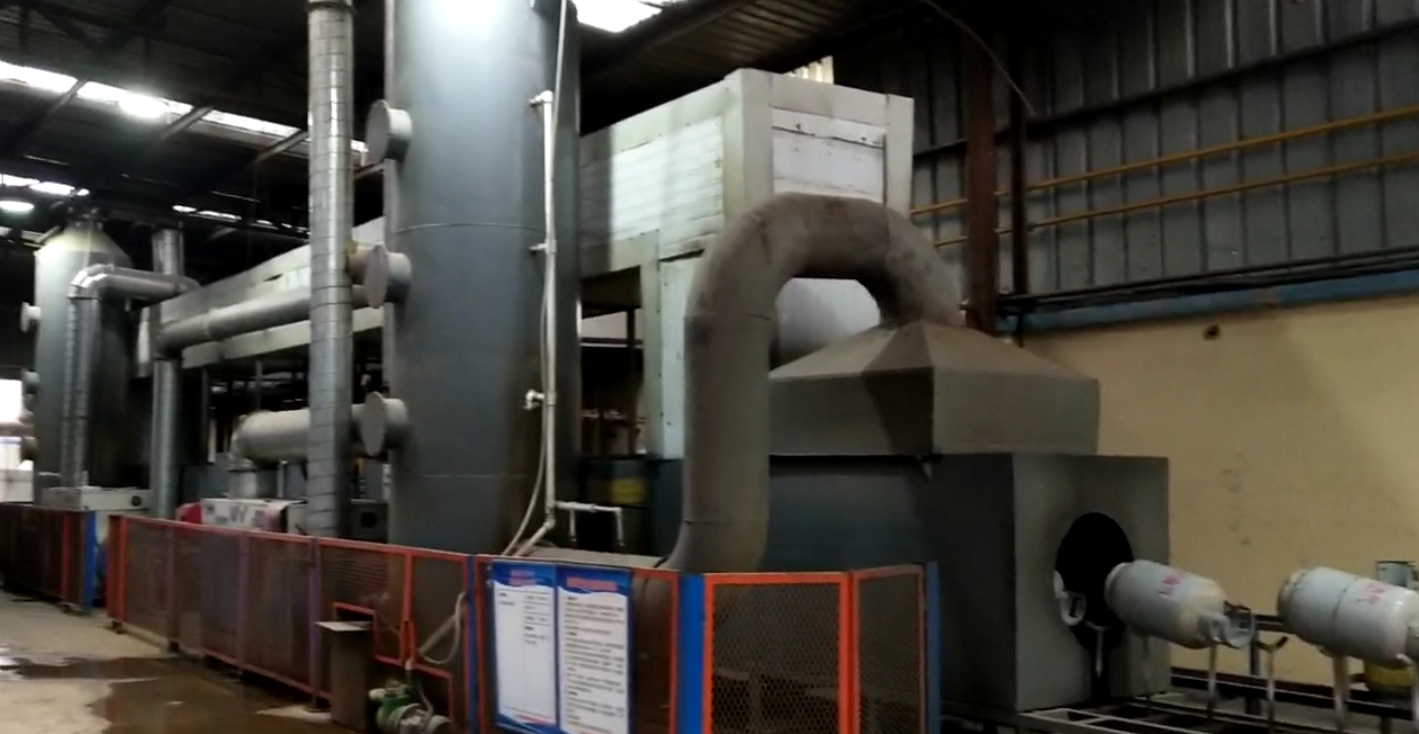

For the testing line of the cylinder test equipment, in fact, it is to a large extent that should pay attention to have a certain degree of automation, and then, in a very large extent, in fact, it will directly realize the flow-shop, greatly improving its own detection efficiency, to ensure the quality of detection.

Gas cylinder testing equipment for the gas cylinder testing process is actually including the registration of bottles, there is also including nitrogen replacement, unloading valve, next, we are actually to pay attention to a certain extent directly on the internal cleaning. When we use the gas bottle test equipment, in fact, Gas Cylinder Testing Equipments it is to pay attention should be to the outer surface of the cylinder to clean, for its appearance, interior and so on thickness measurement, the final air tightness test.

unloading-valve-machine.jpg)